Our Timbertunnel is a custom designed rigid timber framed polytunnel designed and made by us in the Scottish Highlands.

Design Ethos

The Timbertunnel was designed over several years and has gone through many iterations before finally being first built in 2022 on our croft. My aim was to build a strong, and long-lasting polytunnel that was made using sustainable materials.

The arched shape and use of timber for framing polytunnels is not new; there are several examples in the US, and some in the UK, generally known as “gothic arch greenhouses”. When designing ours I researched lots of different designs, before settling on our own version which was specifically intended to use locally grown timber direct from sawmills, and, due to our Highland location it also needed to be very strong. The Timbertunnel has already generated a lot of interest and won a design award for its innovative use of materials.

Models & Dimensions

We offer three different Timbertunnel models. The original Timbertunnel is 4.2m wide and available in any length from 4.2m. We don’t recommend going above 12.8m long as ventilation can become an issue. This width gives a good balance of growing space, while keeping the tunnel not too tall, which would be a problem for windy sites. The height to the ridge is approximately 2.7m.

We also offer a smaller 3.2m wide version. Again it is availble in 1m increments with the smallest size being 3.2 x 3.2m.

New for 2024, we now make a 2.4m wide version too, perfect for smaller gardens or as a dedicated potting area. This version is prebuilt in our workshop and delivered to you fully assembled. We need a 2.5m wide access to install this size tunnel, though we can also hire a crane if necessary.

Scottish Timber

The Timbertunnel has sustainability at its heart. Locally grown timber from sustainably managed forests is one of the best building materials we have. It locks up carbon and is durable. We use douglas fir and larch as these are long lasting outdoors and don’t require treatment.

Most timber bought from hardware stores and timber merchants is imported and treated with chemicals. The transport costs of this material are huge. The UK is the second largest net importer of timber in the world and it is important to develop products that support our timber industry and use our homegrown resources. We work with various local sawmills such as Logie Timber in Moray who are as passionate as us about where their timber comes from and how our forests are managed sustainably.

The timber is cold bent and laminated to form the curved ribs. This process creates an incredibly strong structure – you can actually stand on the ridge! I’m not sure there are many other tunnels you can do this on!

Polycarbonate Sheeting

A key part of the Timbertunnel concept was to reduce waste. Traditional polytunnel plastic has a short lifespan, is not recyclable and ends up in landfill. It is also not very durable and isn’t ideal for the Scottish climate.

We use twinwall polycarbonate which is very durable. The manaufacture guarantees it for 10 years but polycarbonate has a lifespan well over double that. Added to this, it also creates excellent growing conditions. The twin wall design traps air and therefore adds insulation, holding its heat far longer than a normal polytunnel. It also dissipates the light very well with excellent light transmission and is UV treated.

We use 10mm thick polycarbonate for our tunnels. Our design is optimised to reduce waste and less than a bin bag of offcuts will be produced for each tunnel (and we’re looking to make this zero!)

One final benefit is impact resistance – the tunnel is likely to survive being hit by debris far better than a normal polytunnel or glasshouse.

We work with a UK based manufacturer of polycarbonate sheets, who have strong environmental credentials, with factories powered by renewables and who are continually reducing their environmental impact, by reducing packaging and waste, and improving recyclability.

We supply polycarbonate in clear as standard, but opal-tinted sheets are also available if you wish to use your tunnel for other uses other than growing crops and want to reduce the temperature and direct sunlight. The opal tinted polycarbnate is even recycled!

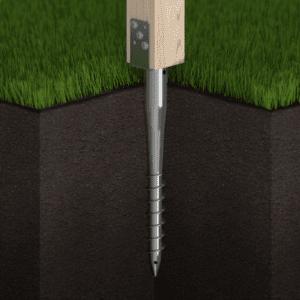

Foundations

The Timbertunnel is designed for strong winds and harsh climates so the foundations need to be strong. We didn’t want to default to concrete as cement has a very high environmental cost (the cement industry is responsible for 5% of the world’s CO2 emisssions!). Instead we use galvanised steel groundscrews from a Scottish company, Radix – these are very strong, quick to install and don’t involve any digging! It also means the tunnel can be removed in the future with no trace.

They aren’t suited to all sites though, so if you have very rocky ground or shallow soil, we will use durable galvanised steel posts concreted into the ground.

Siting your Timbertunnel

There are a lot of factors to consider when siting your Timbertunnel. As the tunnel has excellent light transmission, orientation is not critical, but North-South is best to give minimal shading throughout the day. Probably more important is for the door to not be facing the prevailing wind on an exposed site, and equally the tunnel will resist wind better if sited side-on to prevailing winds. Although our design is very strong, it is still worth chosing a sheltered spot if this is possible – it will make your tunnel much nicer to use if anything.

It is well worth siting the tunnel close to your home or somewhere easily accessible. It is a lovely place to spend time in and you will use it more than you think! The Timbertunnel looks the part and does not need to be hidden away down the bottom of the garden!

The ground will need to fairly flat and you will need to dig it out to be exactly level. Digging into a slope is possible but consider drainage. You will also need a water supply nearby.

If you have very poor soil you may want to consider building raised beds inside and bringing in new soil or mulches. On our tunnel we grow directly in the ground with a no-dig system. We use compost, seaweed and woodchip to improve the soil and dug out the paths and filled them with woodchip.

Of course you may wish for your Timbertunnel to be a multi-use space and add decking, paving etc. In our cold and windy Scottish climate it is truly wonderful to have a warm, light and sheltered space to enjoy lunch or an evening beer.

Any Questions? Check our FAQ page

Technical Specifications

| Outer Width | TT4: 4.2m (13.8′) | TT3: 3.2m (10.5′) | TT2: 2.4m (8′) |

| Inner Width | TT4: 4.1m (13.5′) | TT3: 3.1m (10.2′) | TT2: 2.3m (7.7′) |

| Length | From 3.2m (10.5′) in increments of 1.06m up to 12.7m (41.7′) |

| Height | Height to ridge: TT4: 2.7m (9′) | TT3: 2.5m (8.2′) | TT2: 2.4m |

| Rib (framework) | Laminated douglas fir timber; 115 x 50mm |

| Additional framework | Douglas fir 50 x 50mm |

| Base framework | Larch 150 x 50mm |

| Cover material | 10mm twinwall polycarbonate sheeting (warranty 10 years) |

| Ridge capping | 1mm aluminium |

| Hardware | Fully galvanised throughout |

| Fixings | All exterior grade screws and bolts used |

| Foundations | 86cm galvanised groundscrews OR galvanised steel concreted posts |

| Stable Door | 195 x 105cm for wheelbarrow access (standard version) |

| Window | 100 x 105cm hinged window / vent (standard version) |

| Optional | Stable door each end; extra gable windows; potting bench; raised beds. |